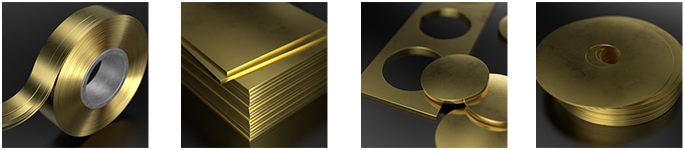

NICLAFOR 1000

CuNi9Sn6

Cu reste Ni8.5-9.5 Sn5.5-6.5

| Chemical composition |

|---|

CuBAL

Ni8.5-9.5

Zn0.5 max

Pb0.02 max

Sn5.5-6.5

Fe0.5 max

Mn0.05-0.30

Mg0.15 max

OtherNb 0.1 max

| Alloy name | |

|---|---|

| RLSA no. | 560 |

| EN standard | |

| DIN standard | |

| UNS no.* | C72700 |

*Unified Numbering System (USA)

Characteristics and main uses

Niclafor 1000® is a Copper-Nickel-Tin (CuNi9Sn6) based alloy with high strength and low thermal conductivity. The high strength and excellent resistance to thermal relaxation are derived from spinodal decomposition. The combination of strength and formability is similar to that of beryllium copper and titanium copper alloys.

Main uses

Electronics industry uses CuNi9Sn6 for springs, miniaturized signal connectors and EMI shields.

Additionally, the high strength allows Niclafor 100 to be used in eyeglass arms and hinges as well as mechanical components in wristwatches.