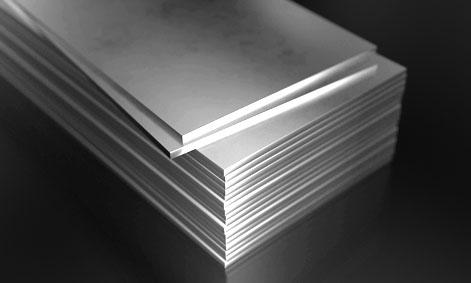

At ROBERT LAMINAGE, custom-made is a trademark. We have a solution for every application, which represents an infinity of possibilities in terms of alloys and services. We can manage a stock of finished parts on request, for example.

Our objective above all is to offer our customers as much flexibility as possible, together with advice, through close collaboration.