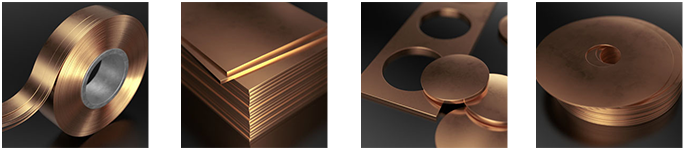

AM388

CuNi8Sn5

Cu reste Ni7-8 Sn4.5-5.5

| Chemical composition |

|---|

CuBAL

Ni7.0-8.0

Zn0.1 max

Pb0.01 max

Sn4.5-5.5

Fe0.1 max

Mn0.1 max

| Alloy name | |

|---|---|

| RLSA no. | 555 |

| EN standard | |

| DIN standard | |

| UNS no.* | C72650 |

*Unified Numbering System (USA)

Characteristics and main uses

AM388 alloys are essentially made of copper, nickel and tin Cu Ni8 Sn5. This alloy is produced by powder metallurgy, and delivered in strip, wire or foil form. It offers a set of properties that make it ideal for the manufacture of a wide range of parts used in a wide variety of fields: electronics, watchmaking, eyewear, etc. A simple heat-tempering treatment enables Spinodal decomposition hardening to produce very high mechanical properties.

For further information, please ask for our technical brochure.

| Physical properties | Units | |

|---|---|---|

| Density (20°C) | 8,87 | Kg/dm³ |

| Melting point | 1120 | °C |

| Longitudinal elasticity modulus | 127 | GPa |

| Thermal conductivity | W/m·K | |

| Electrical conductivity | >4.7 | m/Ω·mm² |

| Electrical resistivity | <0.215 | µΩ·m |

| Linear expansion Coefficient | 16,4 | 10⁻⁶·K⁻¹ |

| IACS (International Annealed Copper Standard) | 8 | % |

| Poisson's ratio |

| Capabilities | |

|---|---|

| Corrosion resistance | 4 |

| Hot deformation | 1 |

| Cold deformation | 4 |

| Electrodepositing | 3 |

| Diamond cutting | 4 |

| Nitriding | |

| Mechanical polishing | 4 |

| Welding without filler | 4 |

| Brazing | 3 |

1 poor | 2 average | 3 good | 4 very good | - no info