CuNi12Zn25Pb

MAILLECHORT Pb

Cu60-63 Ni11-13 Zn reste Pb0.5-1.5

| Chemical composition |

|---|

Cu60-63

Ni11-13

ZnBAL

Pb0.5-1.5

Sn0.2 max

Fe0.3 max

Mn0.5 max

Other0.2 max

| Alloy name | |

|---|---|

| RLSA no. | 490 |

| EN standard | CW404J |

| DIN standard | CuNi12Zn25Pb1 |

| UNS no.* | C79200 |

*Unified Numbering System (USA)

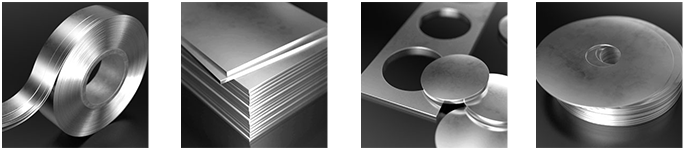

Characteristics and main uses

CuNi12Zn25Pb is a nickel-silver alloy containing 12% nickel and 25% zinc. The addition of lead makes it suitable for machining operations. It also has good stamping properties and good corrosion resistance.

Main uses

Deep drawn parts, Tableware, Security keys, Cutlery, Watch movement parts