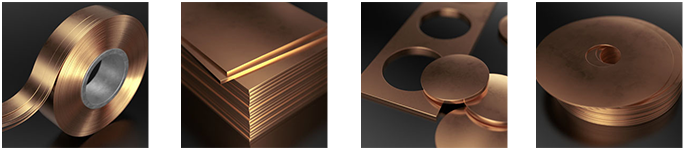

NKT322

CuFeTi

Cu reste Fe0.17-0.23 Ti2.9-3.4

| Chemical composition |

|---|

CuBAL

Fe0.17-0.23

Ti2.9-3.4

Other0.5 max

| Alloy name | |

|---|---|

| RLSA no. | 135 |

| EN standard | |

| DIN standard | |

| UNS no.* | C19910 |

*Unified Numbering System (USA)

Characteristics and main uses

NKT322 GIGALLOY is a titanium-copper alloy independently developed by JX Nippon Mining & Metals Corporation. By adding Fe to C1990, a conventional titanium-copper alloy, and optimizing treatment processes, NKT322 GIGALLOY offers significantly improved mechanical properties and deformation characteristics. The excellent balance of its mechanical properties means that it is widely used for switches, connectors and other electronic components. NKT322 GIGALLOY is recognized as the best alternative to copper-beryllium.

◆ Features

1. A beryllium-free copper alloy with ultra-high resistances

2. Excellent mechanical strength and deformation characteristics equal to or better than those of copper-beryllium in the hardened state; often used as an alternative alloy

3. Highest level of stress relaxation resistance among copper alloys; maintains contact force at high temperatures.

| Physical properties | Units | |

|---|---|---|

| Density (20°C) | 8,70 | Kg/dm³ |

| Melting point | 965-1055 | °C |

| Longitudinal elasticity modulus | GPa | |

| Thermal conductivity | W/m·K | |

| Electrical conductivity | m/Ω·mm² | |

| Electrical resistivity | 0.132-0.172 | µΩ·m |

| Linear expansion Coefficient | 18 | 10⁻⁶·K⁻¹ |

| IACS (International Annealed Copper Standard) | 10-13 | % |

| Poisson's ratio |

| Capabilities | |

|---|---|

| Corrosion resistance | |

| Hot deformation | |

| Cold deformation | |

| Electrodepositing | |

| Diamond cutting | |

| Nitriding | |

| Mechanical polishing | |

| Welding without filler | |

| Brazing |

1 poor | 2 average | 3 good | 4 very good | - no info