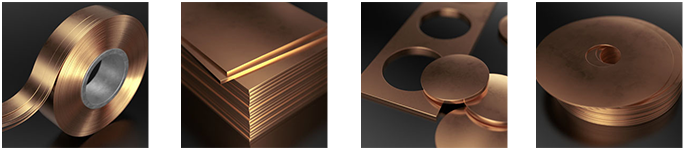

Cu ETP

COPPER - CuA1

Cu>99.9 O0.04 max

| Chemical composition |

|---|

Cu99.9

Pb0.005 max

O0.005-0.04

| Alloy name | |

|---|---|

| RLSA no. | 100 |

| EN standard | CW004A |

| DIN standard | 2.0065 |

| UNS no.* | C11000 |

*Unified Numbering System (USA)

Characteristics and main uses

Cu-ETP is an electrolytically refined copper containing oxygen. It has very good electrical conductivity and is economically attractive compared to other high conductivity copper alloys.

Due to the residual oxygen content, the alloy is not suitable for welding as it is susceptible to hydrogen embrittlement.

Electrical conductivity depends on chemical composition, cold deformation level and particle size. A high level of strain as well as a small grain size decreases the conductivity.

ETP copper is resistant to natural and industrial atmospheres as well as maritime air, drinking and service water, non-oxidizing acids, alkaline solutions and neutral salt solutions.

ETP copper is not resistant to ammonia, halide, cyanide and hydrogen sulfide solutions and atmospheres, oxidizing acids and seawater (especially at high flow rates).

Due to its oxygen content, Cu-ETP is not resistant to hydrogen embrittlement in reducing atmospheres at elevated temperatures.

Main uses

Architectural ironwork, gutters, flashings, roofs, downspouts, perforated metal screens, automotive and industrial radiators, electrical conductors, contacts, terminals, chemical processing equipment, kitchen needs, electric percolator bodies, lamps, dishes and planters for the home and the office.