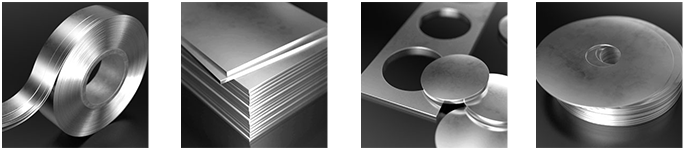

CuNi12Zn24

MAILLECHORT

Cu63-66 Ni11-13 Zn reste Pb0.03 max

| Chemical composition |

|---|

Cu63-66

Ni11-13

ZnBAL

Pb0.03 max

Sn0.03 max

Fe0.3 max

Mn0.5 max

Other0.2 max

| Alloy name | |

|---|---|

| RLSA no. | 400 |

| EN standard | CW403J |

| DIN standard | 2.0730 |

| UNS no.* | C75700 |

*Unified Numbering System (USA)

Characteristics and main uses

CuNi12Zn24 is a nickel silver alloy which is alloyed with 12% nickel and 24% zinc. It is easy to cold-form and has particularly good deep-drawing properties. Like all copper materials, the copper-nickel-zinc alloys show no tendency to embrittlement at lower temperatures. The corrosion resistance of nickel silver is much better than that of binary copper-zinc alloys. NB12 is insensitive to stress corrosion cracking. NB12 is used for contacts, deep drawn parts and for optical goods. This alloy is registered with U.S. EPA as antimicrobia

Main uses

Coins, Caps for crystals, Electromagnetic shielding, Deep drawn parts, Tableware, Security keys, Cutlery, Contact springs, Connectors, Relay springs and Electrical contacts