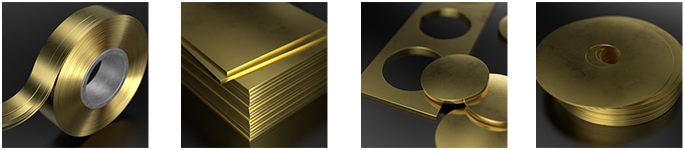

CuZn15

TOMBAC

Cu84-86 Zn reste

| Chemical composition |

|---|

Cu84-86

Ni0.3 max

ZnBAL

Sn0.1 max

Fe0.05 max

| Alloy name | |

|---|---|

| RLSA no. | 250 |

| EN standard | CW502L |

| DIN standard | 2.0240 |

| UNS no.* | C23000 |

*Unified Numbering System (USA)

Characteristics and main uses

CuZn15 is a solid solution strengthened copper alloy containing 15% zinc (brass). It has very good cold formability and is suitable for bending, stamping and other cold forming processes. The alloy can be welded or brazed. As zinc content increases, strength improves, but conductivity and ductility are reduced. CuZn15 has good resistance to stress corrosion cracking, but the alloy must be relaxed if exposed to an ammonia atmosphere.

| Physical properties | Units | |

|---|---|---|

| Density (20°C) | 8,75 | Kg/dm³ |

| Melting point | 1020-1030 | °C |

| Longitudinal elasticity modulus | 122 | GPa |

| Thermal conductivity | W/m·K | |

| Electrical conductivity | >17.40 | m/Ω·mm² |

| Electrical resistivity | <0.0575 | µΩ·m |

| Linear expansion Coefficient | 18,5 | 10⁻⁶·K⁻¹ |

| IACS (International Annealed Copper Standard) | >30 | % |

| Poisson's ratio |

| Capabilities | |

|---|---|

| Corrosion resistance | 4 |

| Hot deformation | 2 |

| Cold deformation | 3 |

| Electrodepositing | 4 |

| Diamond cutting | |

| Nitriding | |

| Mechanical polishing | 4 |

| Welding without filler | 3 |

| Brazing | 4 |

1 poor | 2 average | 3 good | 4 very good | - no info