POLIDUR

X2 NiCoMo18-16.5-5

Fe reste Ni17-19 Co16-17 Mo4.5-5.5

| Chemical composition |

|---|

Ni17-19

FeBAL

Co16-17

Mo4.5-5.5

| Alloy name | |

|---|---|

| RLSA no. | 971 |

| EN standard | |

| DIN standard | |

| UNS no.* |

*Unified Numbering System (USA)

Characteristics and main uses

High elastic limit alloy, very resistant, allowing the production of spring parts. A very high quality polished surface can be obtained with this alloy compared to YAG 250RL and RODUR. This is thanks to the absence of titanium in the chemical composition.

- Superior formability and extremely high mechanical properties after aging, thanks to intensive precipitation with moderate temperature hardening heat treatment. This treatment can be done after shaping because it causes very little dimensional change.

- No weakening at low temperature.

- Excellent resistance to fatigue.

- Structural stability after aging.

- Low thermoelastic coefficient.

- Excellent weldability. The post-weld hardening treatment significantly reduces the differences in properties between welded and non-welded areas, thereby eliminating weak spots.

- No TiN => better properties for polishing

Main uses

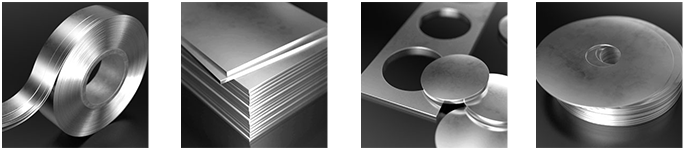

PHYTIME® is specially designed for all applications requiring high resistance to fatigue, such as those used in the automotive industry:

- Belt for automatic gearbox

- Cable connectors to motors

- Springs

- Automotive, injection

- Watchmaking