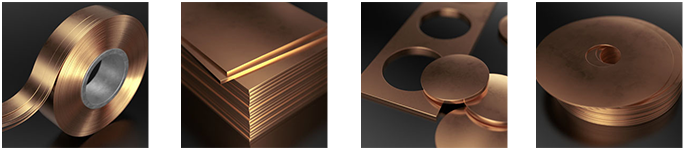

Cu OF

COPPER - CuC1

Cu>99.99 O0.001 max

| Chemical composition |

|---|

Cu99.99

Pb0.005 max

O0.001 max

| Alloy name | |

|---|---|

| RLSA no. | 125 |

| EN standard | CW008A |

| DIN standard | 2.0040 |

| UNS no.* | C10200 |

*Unified Numbering System (USA)

Characteristics and main uses

Cu-OF is a high conductivity oxygen-free copper with a minimum of 99.99% Cu. It offers the benefits of hard electrolytic copper (ETP) and phosphorus deoxidized copper. The high purity and absence of deoxidizers account for the 100% electrical conductivity of IACS as well as the absence of hydrogen embrittlement. Cu-OF has very good formability and can be brazed and welded, making it superior to Cu-ETP in these aspects.

The main areas of application are very critical electrical, electronic and communication components.

Copper is resistant to natural and industrial atmospheres as well as maritime air, drinking and service water, non-oxidizing acids, alkaline solutions and neutral salt solutions.

Copper is not resistant to ammonia, halide, cyanide and hydrogen sulfide solutions and atmospheres, oxidizing acids and sea water (especially at high flow rates).

Main uses

Radar components, electrical engineering components, conductors, contacts and terminals, printed circuits and flexible circuits