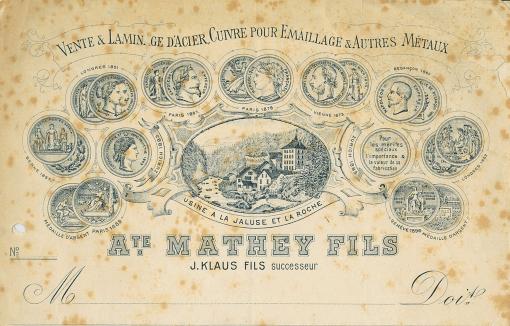

Since 1836, our family business ROBERT LAMINAGE has manufactured metal strips and foils with the utmost precision.

We supply a very wide range of alloys, covering the most stringent industrial requirements. We have also developed a unique know-how in the design of custom solutions for special applications.

Mission

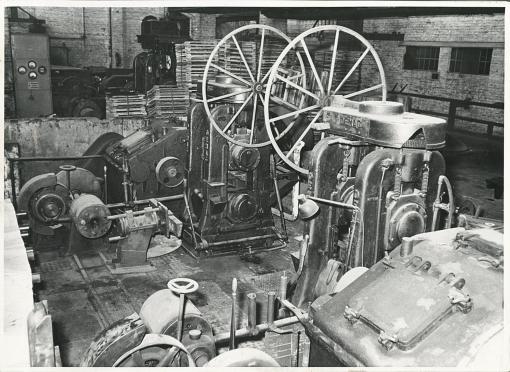

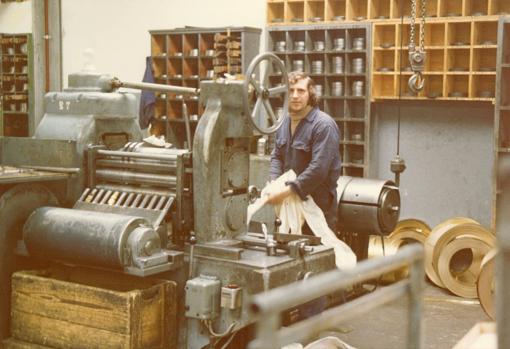

Our business has specialised in rolling for generations, without interruption. We have developed a unique industrial know-how, which defines us as an absolute benchmark in our field. We do not make any compromises on the quality of our products, just as we remain inflexible in terms of the values underpinning our reputation and guaranteeing our long-term future. We have inherited a spirit of innovation, which we cultivate with passion and honesty. We listen to our customers, and believe firmly in relationships based on partnership and trust. Every day, we work to improve our environment so that future generations continue to benefit from this immense know-how.

Vision

ROBERT LAMINAGE has for more than 50 years been a favoured partner of watchmaking, a field which has constantly been enhanced by its know-how in terms of rolling. Now we want to actively step up our diversification to all cutting-edge industries requiring the development of high-quality rolled alloys, such as the medical, aeronautic or transport industries. The miniaturisation of all the equipment has advanced our capacity to roll ultra-thin strips and produce small runs efficiently. From generation to generation, our company has proudly embodied the values of SWISS MADE: precision, know-how and respect.